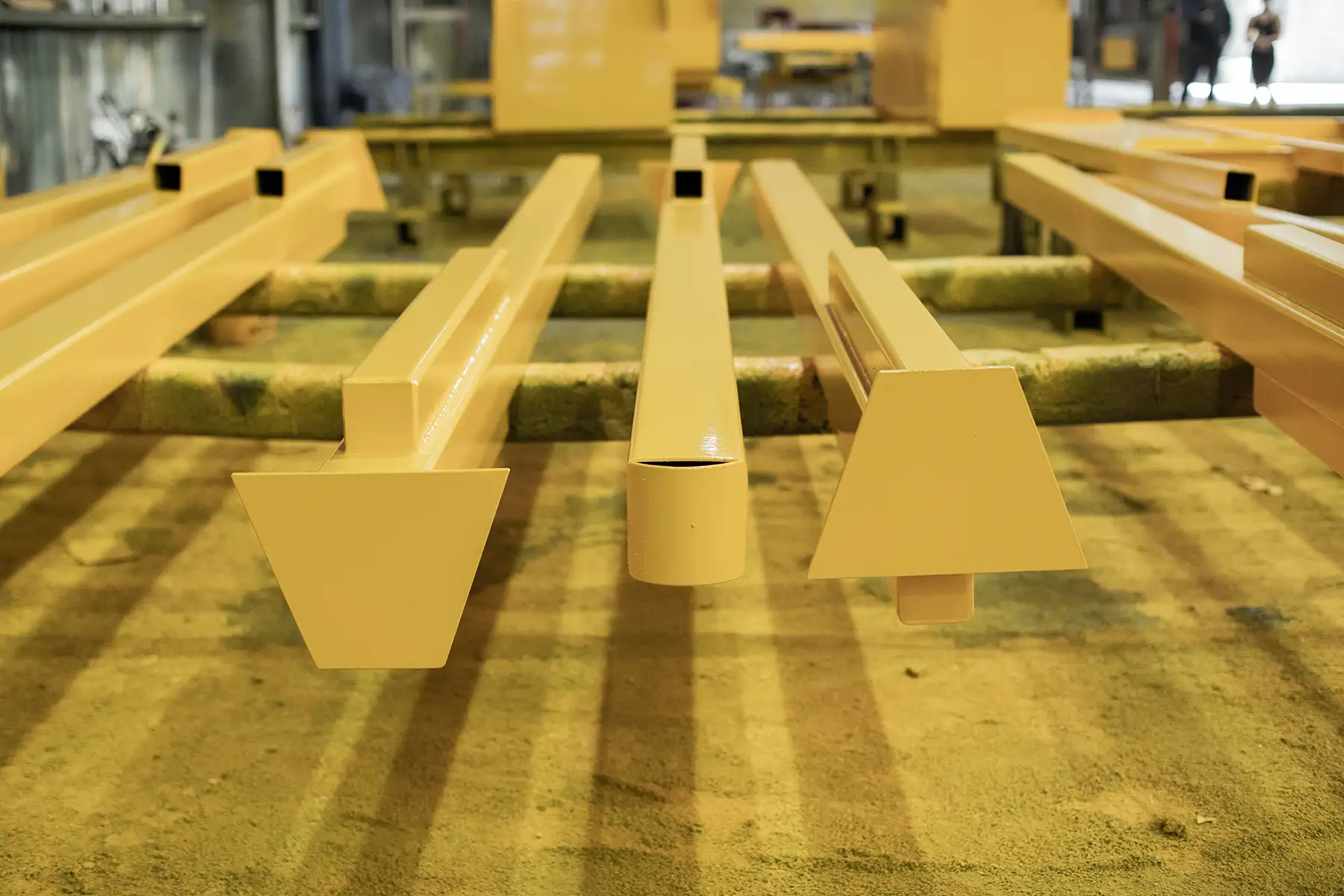

At Blastcoat, we pride ourselves on being an Abrasive Blasting Specialist in Newcastle, offering top-notch surface preparation services for steel structures.

Abrasive blasting is a critical step in ensuring the longevity and durability of protective coatings, whether it’s for new steel or refurbishing older materials.

With our advanced techniques and industry expertise, we deliver outstanding results that ensure your steel surfaces are clean, smooth, and ready for the next stage of their lifecycle.

Industrial painting plays a crucial role in the longevity and durability of various steel structures.

As a protective measure, steel painting goes beyond aesthetics, providing a safeguard against corrosion, weathering, and wear.

Without proper industrial painting, steel surfaces are left vulnerable to rust, which can weaken the structural integrity of a building or infrastructure over time.

At Blastcoat, we deliver top-tier fire protection solutions for a wide range of projects.

Whether it’s for interior or exterior applications, our intumescent coatings ensure your steel structures are safeguarded in the event of a fire, without compromising aesthetic quality.

Blastcoat are approved applicators for numerous Intumescent coating suppliers, such as

Our Site Services team integrates seamlessly with project schedules and adapts to our clients’ specific requirements, ensuring minimal disruption and maximum efficiency.

Each member of our team is fully trained and licensed, meeting the highest industry standards to ensure tasks are performed safely and effectively.

Whether working on large-scale industrial projects or smaller, complex jobs, we bring the right expertise to deliver quality results.

In industries where equipment is exposed to wear, corrosion, or chemical damage, the need for high-quality protective coatings is essential.

Blastcoat Protective Coatings offer tailored protective coating solutions such as rubber and ceramic lining to safeguard valuable assets by creating a barrier that prevents the underlying material from coming into direct contact with corrosive substances or abrasive materials.

At Blastcoat, we recognise the importance of quality assurance in every project.

Our Independent Inspection Services provide an additional layer of protection, ensuring that our clients receive the highest level of service, from the preparation stages to the final application.

This commitment to thorough inspection ensures that all coatings are durable, effective, and built to withstand even the harshest conditions.

Let our Abrasive Blasting and Protective Coating specialists bring out the best in your project.

By clicking on the button above, you accept our privacy policy