Our Site Services team integrates seamlessly with project schedules and adapts to our clients’ specific requirements, ensuring minimal disruption and maximum efficiency. Each member of our team is fully trained and licensed, meeting the highest industry standards to ensure tasks are performed safely and effectively. Whether working on large-scale industrial projects or smaller, complex jobs, we bring the right expertise to deliver quality results.

We understand the importance of staying on track, which is why we use a purpose-built site truck, fully equipped with advanced blasting and painting equipment. This allows us to reduce mobilisation costs, and efficiently manage work fronts on-site, ensuring projects are completed on time and within budget.

Methods like sandblasting and dust free vacuum blasting involve blasting abrasive materials like sand, steel grit, or aluminium oxide at high velocity to clean or prepare surfaces for coating adhesion or aesthetic purposes.

Tailored for large commercial and industrial applications, this heavy-duty process is used to maintain or restore machinery, equipment, pipelines, and structures by removing grime, corrosion, and old coatings.

Whether you’re after metal blasting or large scale industrial blasting solutions, Blastcoat has a team of experts to provide the best solution for each project’s needs.

Protective coatings, such as epoxy, zinc, polyurethane, or specialised steel coatings are applied to surfaces to shield them from corrosion, UV exposure, wear, and chemical damage, ensuring longevity in harsh environments.

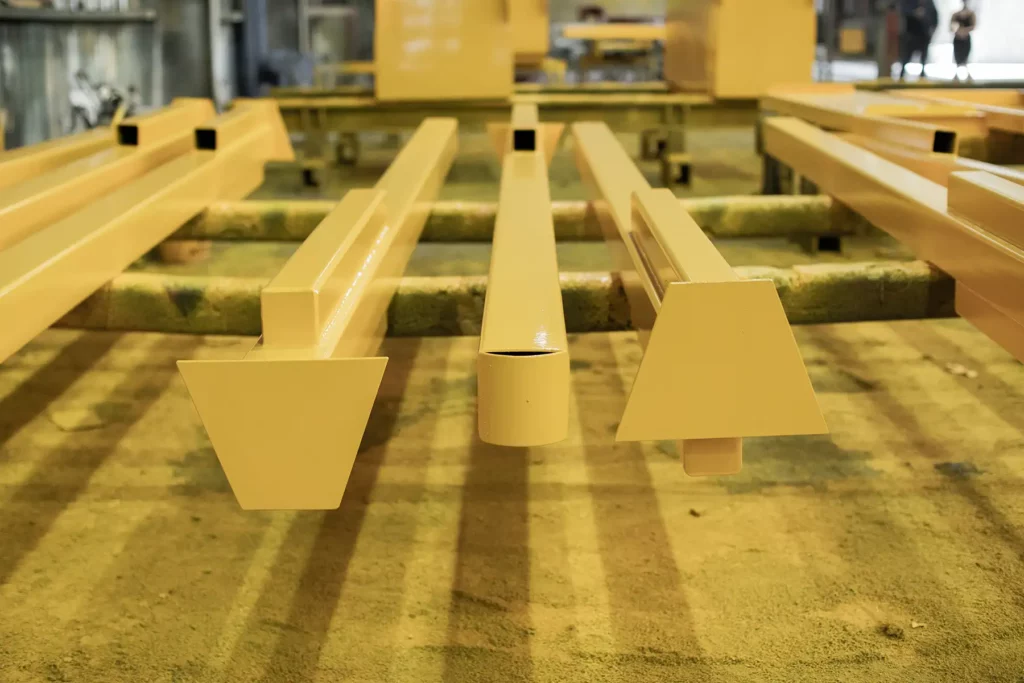

Blastcoat also offer dry finishing or powder coatings processes where powdered paint is applied electrostatically and cured under heat. It provides a smooth, durable finish resistant to corrosion, chemicals, and the elements. This process is commonly used on metal surfaces.

Painting steel surfaces with specialised paints or coatings like zinc primers, epoxy coatings, and polyurethane coatings help to protect them from rust, weathering, and chemical damage. When used as a protective measure, steel painting goes beyond aesthetics, providing a safeguard against corrosion, weathering, and wear, helping to extend the life of steel structures and equipment.

This process involves cutting, bending, and assembling metal components to create structures or machinery parts. The metal fabrication process is key in industries that require durable and precise components. It allows for the creation of custom metal products tailored to specific needs, whether for large-scale infrastructure projects or intricate machinery.

Contact Blastcoat today for expert site services that deliver minimal disruption and maximum efficiency.

Let our Abrasive Blasting and Protective Coating specialists bring out the best in your project.

By clicking on the button above, you accept our privacy policy